How To Read Recordall Transmitter Register

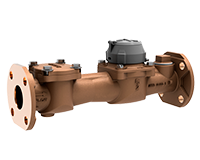

T450 3″ – Recordall® Turbo Series Meters

Recordall ® Turbo Series meters run into or exceed the most recent revision of AWWA Standard C701 Class Two Standards and are bachelor in a lead-free bronze alloy for sizes one-1/2″ through 10″ and bandage iron for 12″ meters. Turbo Series meters comply with the lead-free provisions of the Safe Drinking H2o Human action. Sizes 1-1/two″ through 10″ meters are also certified to NSF/ANSI Standards 61 and 372 (Trade Designation: Turbo Series LL-NS) and carry the NSF-61 marker on the housing. All components of the atomic number 82-free blend meter (housing, measuring element, seals and so on) comprise the certified system.

Models 160 through 6200 are designed for 1-1/2″ through 12″ applications. These meters feature:

- Direct coupled turbine based on an sectional "floating rotor" blueprint that reduces begetting friction—and associated wear and tear.

- Low pressure loss for improved system efficiency.

- Exceptional registration accuracy across low flow rate, normal operating flow charge per unit and maximum continuous operation menstruum.

- Permanently sealed, tamper-resistant annals or encoder.

- Integral strainer option for sizes one-i/two″ through 4″ assist protect your system from dissentious debris and related downtime.

- Meters and encoders are uniform with Badger Meter AMR/AMI meter reading systems and other approved reading technologies.

- Description

- Additional data

Clarification

Applications: Recordall Turbo Series meters are designed for cold water, commercial and industrial applications where flows are consistent medium to loftier flows. Applications include hotels, apartment buildings, irrigations centers and manufacturing and processing plants. Turbo Serial meters help reduce day-today maintenance costs while delivering accurate and efficient performance.

Operation & Performance: Direct magnetic bulldoze is achieved when the magnet carrier is driven by a gear railroad train coupled to the rotor. The gear train consists of ii sets of gears continued past a vertical manual shaft. One gear fix is at the magnet carrier, the other is a worm gear fix at the rotor shaft. When water flows into the Turbo Serial meter measuring element, it contacts the multi-vaned rotor. The resulting rotor rotation is and so transmitted past magnetic coupling to a sealed register or encoder. The directly magnetic drive is congenital to provides a reliable meter-to-registration coupling.

Tamper-Proof Features: Unauthorized removal of the register or encoder is inhibited by the option of a tamper detection seal wire screw, TORX® tamper-resistant seal screw or the proprietary tamper-resistant keyed seal screw. Each can be installed at the meter site or at the factory.

Construction: The Recordall Turbo Series meter is constructed in compliance with ANSI and AWWA C701 standards. It consists of the following basic components: meter housing, interchangeable, unitized measuring element and permanently sealed direct reading registers or encoders.

The measuring element consists of the manual coupling, rotor, inlet and outlet straightening vanes with nose cones, and calibration band assembly. The unique inlet and outlet straightening vanes minimize swirl from piping arrangements upstream too as downstream.

A strainer is recommended to help ensure optimal menses workout and protection for the measuring element. An integral strainer is available as an option for 1-i/ii″ through 4″ meter sizes. The stainless steel strainer is built into the inlet cease and includes a removable cover plate to permit like shooting fish in a barrel access for routine cleaning. External strainers are bachelor in sizes 2″ through 12″.

To simplify maintenance, the registers or encoders and measuring elements can be removed without removing the meter housing. Interchangeability of sure parts between meters also minimizes spare parts inventory investment.

Meter Installation: The meter is designed for installations where flow is in one direction but. Companion flanges for installation of meters on various pipe types and sizes are available in cast fe or NL bronze every bit an pick. See the Recordall Turbo Series Meters User Transmission for specific instructions.

Additional information

| Meter Flanges AWWA 125 Pound Grade | Round |

|---|---|

| Typical Operating Range (100% ± 1.5%) | 5…550 gpm |

| Typical Low Flow (95% min.) | 4 gpm (0.9 m3/h) |

| Maximum Continuous Flow | 450 gpm |

| Maximum Intermittent Flow | 550 gpm |

| Force per unit area Loss at Max. Continuous Flow | ane.8 psi (0.12 bar) |

| Pressure Loss at Max. Continuous Menstruum: With Integral Strainer | 5 psi (0.43 bar) |

| Maximum Operating Pressure | 150 psi (x bar) |

| Maximum Operating Temperature | 120° F (49° C) |

| Optional Integral Strainer | Built into inlet end. |

| Optional External Strainer | Available |

| Exam Plug | Standard with integral strainer; optional for other models. |

How To Read Recordall Transmitter Register,

Source: https://metertechsolutions.com/product/t450/

Posted by: adamsdiationance.blogspot.com

0 Response to "How To Read Recordall Transmitter Register"

Post a Comment